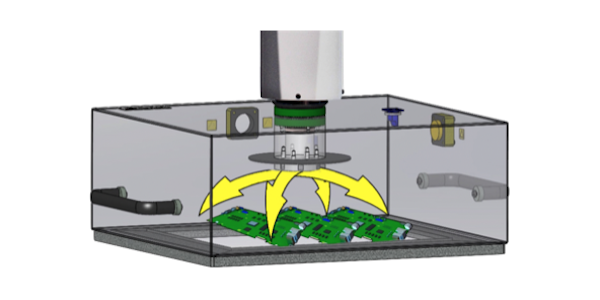

Easily Add Thermal Testing to Industrial PCB Manufacturing Processes

The Problem:

Product reliability challenges over the specified thermal range of your printed circuit boards (PCBs).

Product reliability challenges over the specified thermal range of your printed circuit boards (PCBs).

inTEST Thermal Solutions (iTS) of Mansfield, MA and C1D1 Labs of Carson City, NV have reached an agreement for distribution of process chillers to the cannabis extraction industry.

As scientists and science enthusiasts, we often have a love/hate relationship with technology. On one hand, it enables us to do things better, faster, or more nimbly.

On the other hand it sometimes creates controversies, complications, and difficult questions. The advent of revolutionary ideas like AI and cloud computing in the lab space is no different.

Join inTEST Thermal's managing director, Jean Fallacara, and Cole Parmer's Global Product Manager, David Hayes, and Technical Specialist-Traceable, Cindy Gisler, for a discussion about the outcomes of forward-thinking tech in labs today.

Visit the North Sciences Booth and connect with our team at the Research Supplier Product Show! We'll be talking with researchers from Biogen, MIT, Novartis, and Whitehead Institute about the smartest, safest, -86°C ULT Freezers.