The Mission-Critical Nature of Defence Testing

In the defence industry, the reliability of electronic systems isn't just a specification—it's a matter of national security. Every component, from radar and targeting systems to encrypted communication modules, must perform flawlessly under the most extreme environmental conditions. This non-negotiable requirement places immense pressure on production test engineers to validate performance with absolute precision.

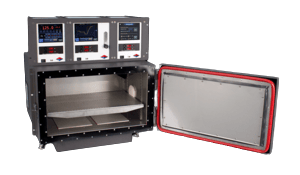

A major defence contractor recently approached InTest Thermal Solutions with a significant challenge: they needed to thermally stress a large, mission-critical Unit Under Test (UUT) as part of their final production qualification process. The UUT's size, mass, and stringent thermal profile rendered standard thermal chambers insufficient. Success required a fully custom-engineered solution.

The Challenge: A Formidable Test Subject

The UUT itself defined the problem. Its specifications immediately eliminated any off-the-shelf option:

- Dimensions: 120cm (L) x 40cm (W) x 40cm (H)

- Weight: 150 Kg

- Temperature Range: +60°C to -40°C

- Transition Rate: 15°C per minute

This was not merely a large and heavy test article; its elongated, long, and narrow shape created a unique challenge for achieving uniform temperature stability across its entire surface. The rapid transition rate, particularly down to -40°C, demanded a powerful and responsive cooling system, for which liquid nitrogen (LN2) was identified as the optimal solution.

Beyond the technical specs, the integration into a production workflow introduced critical logistical and safety hurdles. The UUT required a crane for loading, needed numerous test cables connected to specific points, and had to comply with the customer's rigorous safety protocols.

The InTest Solution: Engineered for Precision, Safety, and Efficiency

InTest engineers developed a tailored LN2-based thermal chamber designed from the ground up to meet this multifaceted challenge. Our solution focused on four critical pillars of performance:

- Advanced Thermal Uniformity Through Custom Airflow Management

Achieving a uniform thermal soak across the UUT's unusual geometry was the primary engineering focus. A standard airflow path would have created hot and cold spots, leading to invalid test results. Our team developed a computational fluid dynamics (CFD) model to design a custom multi-zone airflow system. This system ensures laminar flow is directed precisely around the UUT, guaranteeing that every part of the unit experiences the same thermal environment, thus validating true performance under stress.

- Integrated Structural and Ergonomic Access Features

Loading a 150 Kg unit is not a manual task. We designed the chamber structure with integral overhead crane access points. The chamber features a reinforced load floor and a wide, secure door system that enables the safe and effortless placement and removal of the UUT using the customer's existing production crane, thereby streamlining the test cycle and minimizing manual handling risks.

- Customized Test Access and Connectivity

A complex UUT requires a complex web of monitoring and power cables. We incorporated dedicated, sealed feed-through ports positioned at specific locations on the chamber walls. These custom-configured bulkheads allow engineers to route dozens of test cables directly to their required connection points on the UUT without compromising the chamber's thermal integrity or creating a tangled, inefficient workspace.

- Uncompromising Safety by Design

Safety is paramount. The system was built to incorporate all features mandated by the customer’s safety team. This includes emergency exhaust ventilation for LN2, multi-point emergency stop buttons, continuous oxygen monitoring to prevent hypoxia risk, and robust door safety interlocks that halt operation if access is detected. The chamber doesn't just meet standards; it is a benchmark for safe operation in a production setting.

Conclusion: Ensuring Readiness Through Superior Test Engineering

This custom LN2 thermal chamber is more than just a test box; it is a vital piece of production infrastructure. It ensures that a critical defence asset is proven to be 100% operational across its entire environmental envelope before deployment.

At InTest Thermal Solutions, we specialise in turning unique testing challenges into reliable, turnkey solutions. When your UUT defies convention and your standards demand perfection, our engineering expertise ensures your production line keeps moving forward with confidence.

Is your next project pushing the limits of standard test equipment? Contact the engineers at InTest Thermal Solutions to begin developing your custom solution.