Chiller Refrigeration Systems

High reliability process chillers comprise designs with components that are well-matched to the heat removal task. For long term reliability, especially with low- and ultra-temperature refrigeration systems, designs must balance heat-load management so that each refrigeration stage can effectively manage temperature and pressure without the possibility of overload.

Download the entire brochure "Principles of Fluid Chillers: Design Criteria for Reliable Operation"

As the need for heat removal or cooling capacity increases, refrigeration size and complexity also increase. For liquid chillers, refrigeration circuits are added as cooling requirements address low- and ultra-low temperatures (-40 to -110°C). For example, chillers operating from -40°C to ambient typically use a single-stage refrigeration system. As temperature requirements drop below -40°C, chillers incorporate two-stage and three-stage cooling as well as temperature-specific refrigerants.

For gas chillers, auto-cascade refrigerant designs can also be used where a single compressor works in concert with multiple heat exchangers. Using clean dry air they reach low temperatures more quickly but with less heat capacity than conventional cascade designs.

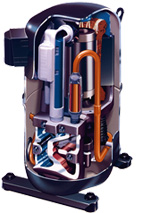

Every element of a chiller – compressor, pump, valves, refrigerants, tubing, controls and more – are critical to the long-term reliability of chiller operation. In fact, the weakest link among these components can bring down the entire system.

Thermonics® uses a refrigeration modeling process, developed in-house, to predict optimal component selection to meet temperature, thermal load and other factors for systems operating at low- and ultra-low temperatures. The resulting process chiller will have more robust components and require fewer moving parts (e.g. valves) over other design methods without overloading any one component.

| Refrigeration System Type | Temperature Range | Typical Heat Transfer Medium |

| Room Temperature - Single Stage Liquid Chiller | 5 to 40°C | Water, Deionized (DI) Water |

| Low Temperature - Single and Dual Stage Liquid Chiller | -20 to -80°C | Above -20°C: Glycol/Water mixture Below -20°C: silicone oils (Dow Dowtherm Q series, Lauda Kryo series, etc.), inert fluorinated fluids (3M Novec Series, Solvey Galden HT series, etc.), alkylated aromatic fluids (Dow Dowtherm series, etc.) |

| Ultra-low Temperature - Triple Stage Liquid Chiller | -80 to -110°C | Inert fluorinated fluids (3M Novec series, Solvey Galden HT series, etc.) |

| Autocascade Gas Chiller | Down to -100°C | Clean Dry Air (CDA), Nitrogen, Argon, etc. |